YAG Laser Overlay and Welding Device

TL Series〈Pulse YAG Laser〉

TL-50/100/150/200

Made in Japan Laser Overlay / Welding Device achieved precise and Higher-Performance more than ever

Enables to precision repairing was not possible to conventional welding method.

Made in Japan Laser Overlay / Welding Device achieved Higher-Performance and Low Cost.

Enables to precision repairing was not possible to conventional welding method.

Made in Japan Laser Overlay / Welding Device achieved Higher-Performance and Low Cost.

TL Series Features

No required advanced skills

Anyone can execute Precision Overlay / Welding by a short time training.

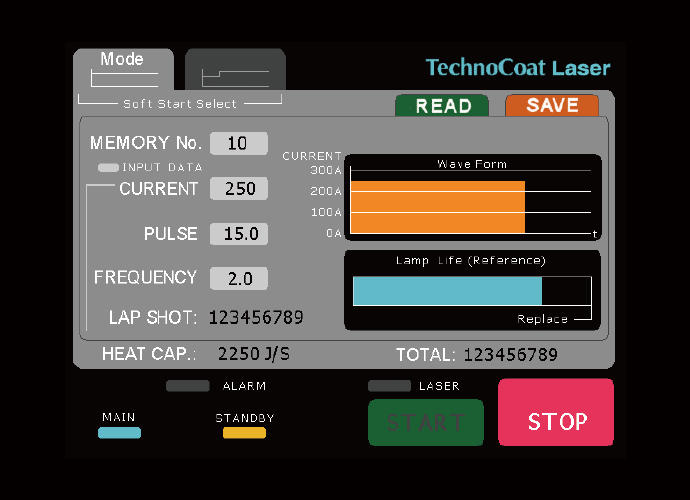

LCD touch panel equipped

Equipped with easy to see and use Color LCD touch panel.

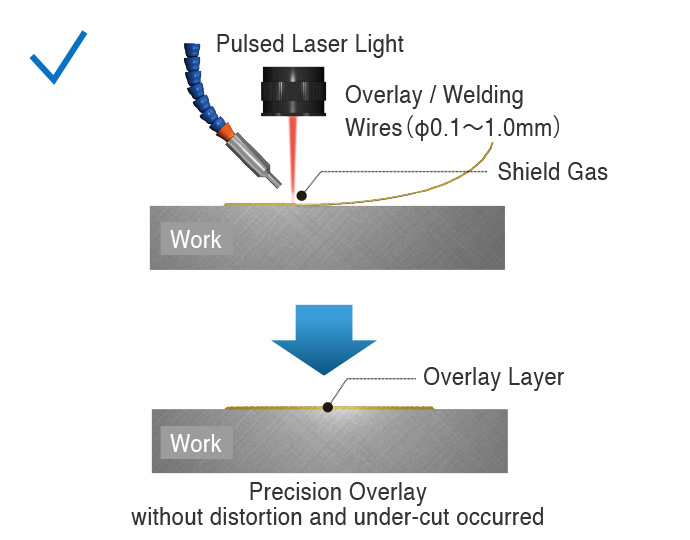

Pulse Spot irradiation

Only Overlay material instantly Melt, and Alloying to Material = Depositing to Material by very low heat input, therefore,

it is possible to provide High Quality Overlay / Welding without adverse effects of heat (Distortion, Under-Cut etc.).

Reducing and suppressing to occur failures like Pin-Holes and Porosity etc

Argon Gas shields to avoid oxidation at Overlay area to provide better quality Overlay is possible.

Control Overlay amount to the minimum

Narrow Groove, Bottom Face of Hole, Side Face, Inner Face, and Inside Corner Fillet etc are executed possibly without requiring Pre-Heating and Post-Heating.

Possible to Overlay / Welding for most of steels

Possible to Overlay / Welding for most of steels, Al, Ti, Cu alloy, SUS, Au, and between Dissimilar Metals, too.

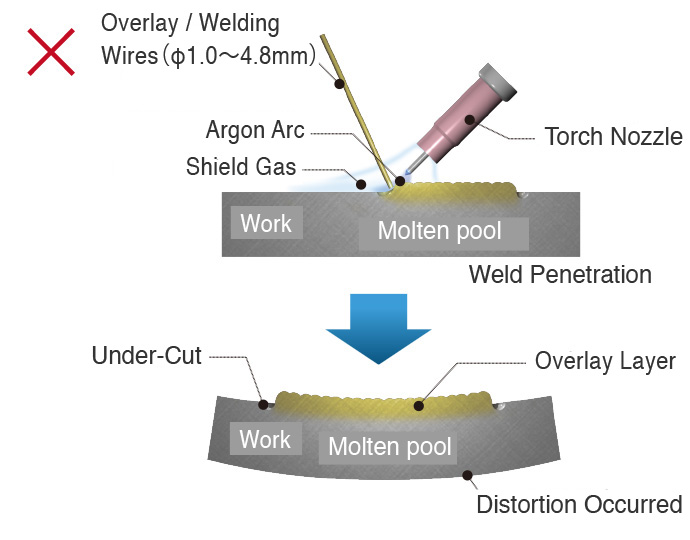

Comparison of Laser Overlay and Argon Overlay

-

Laser Welding

〈Advantages〉

・Easy Operation

・Low-Heat Input

・Precision Overlay / Welding are possible(Reducing Finishing time & Cost)

・Possible to Overlay into narrow grooves, at the bottom face, side face. Inner face & on the fillet or inside corner

・No Pre-Heating & Post -Heating required

〈Dis-Advantages〉

・Slow Overlay to huge area -

Argon Arc (TIG)

〈Advantages〉

・Quick Overlay

・Easy to operate on-side

〈Dis-Advantages〉

・Hight-Skill needed to operate

・High-Heat Imput (Occurs Distortion & Stress)

・Under-Cut occurred

・Larger Overlay amount(Finishing takes much time & costs)

・Difficulty to Overlay into narrow grooves, bottom face, or side face

TL Series Applications

| Die & Mold | Overlay repair for Plastic Injection, Rubber, Glass, Diecasting, Press molds and dies. |

|---|---|

| Machine parts | Overlay repairing for Wear Part, Wound, Pin-Hole, and Processing Failures etc. |

| Welding | Overlay repairing for Under-Cut or Pin-Holes occurred by Argon (TIG) welding method. |

| Precision parts | Precision location welding for various Electronic Components, Sensor, Connectors. |

| Dissimilar metals | Overlay and Welding of Dissimilar Metals. |

| Sheet metal | Overlay and Welding to Sheet Metals of Ti, SUS, and various metals. |

| Medical | Overlay and Welding for Dental Technique or Medical Equipment |

| Marking | Marking on molds, dies, and machinery parts, and Overlay repairing for erasing imprinting and letters. |

| Surface treatment | Overlay repairing of surface treatment by thermal spray, plating, or TD processing. |