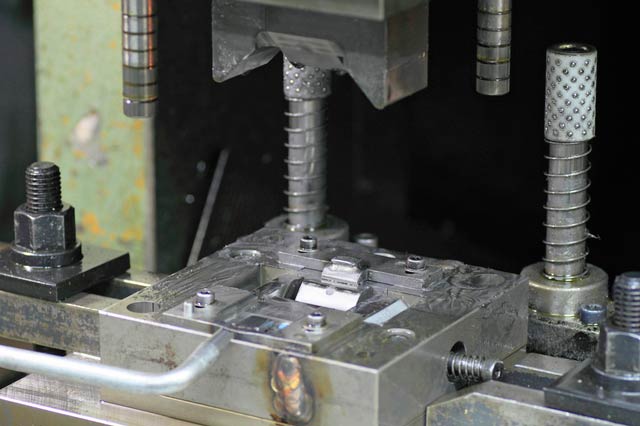

Stress reduction inside the mold improves life and accuracy

Stress is reduced by periodic vibration treatment of the mold

Suppresses mold distortion and extends life

Accumulated stress occurs Heat Checks on surface of Al Diecasting and Casting Dies by repeating Heating (expansion) and Cooling (shrinkage) of these every production cycle.

VibroDyn process is recommended to execute to the die periodically at every 50% numbers of shots to reduce stress, and extending the die’s life longer.

And in a meantime, reducing die’s distortion to keep the accuracy of the product possible.

Example of improving life and accuracy by vibrating the mold

| Type | Part name | Weight (kg) | Material | Purpose / Effect |

|---|---|---|---|---|

| Diecasting | Al Diecasting Die | 500 | SKD-61 | eat Check prevention, products accuracy improvement, during die producing and periodically execution after operation, and during welding repairing to extend the die’s life longer. |

| Mold Mfg. | Plastic Injection Molds | 2,000 | SKD-61 | Execute before and after processing to improve processing accuracy and reducing man-hours. And to prevent distortion by overlay welding of design changes etc. |

Many other applications might be considered. Please contact us about your problem.

Related Product

Vibrational Stress Relief

VibroDyn

VibroDyn is an equipment to alleviate or remove internal stress in metals using vibrational energy

The resonance waveform can be visualized by a simple operation, and the natural resonance point of the workpiece can be detected and easily processed with vibration effective for stress reduction.