Molds and Dies, Mechanical Parts, and Equipments Overlay Repairing

It is possible to provide High Quality Overlay / Welding to various area which was hard to execute before

It is possible to provide High Quality Overlay / Welding to Corner Tip & Edge, Standing Wall, even the narrow Bottom Face area that Torch can not enter are easily executable.

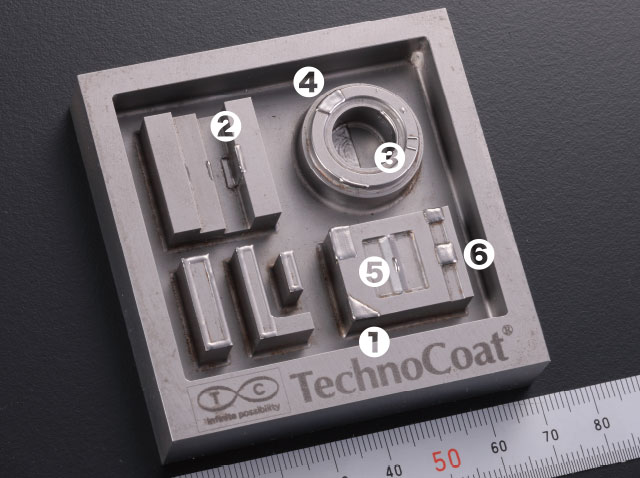

Mold and Dies Overlay Sample (Material: SKD-61)

-

1. Corner Tip & Edge

Without Shrinkage -

2. Standing Wall

Repairable changing by Laser irradiation angle -

3. Bottom Face

Repairable into a narrow area -

4. Curved Surface Easily to Overlay

With Jigs and Motorized Workstation -

5. Acute Angle

Repairable Rubber mold Cutting acute angle area -

6. Gate Filling / Engraving Erasing

Able to do by minimum Overlay amount

Related Product

Portable Fiber Laser Overlay / Welding System

Smart Laser

Super precision laser process for manufacturing and repair

Portable and Maintenance Free achieved Lower Running Cost.

New Fiber Laser Overlay/Welding Equipment.

Portable and Maintenance Free achieved Lower Running Cost.

New Fiber Laser Overlay/Welding Equipment.

YAG Laser Overlay and Welding Device

TL Series〈Pulse YAG Laser〉

Made in Japan Laser Overlay/Welding Device achieved precise and Higher-Performance more than ever

Enables to precision repairing was not possible to conventional welding method.

Made in Japan Laser Overlay / Welding Device achieved Higher-Performance and Low Cost.

Enables to precision repairing was not possible to conventional welding method.

Made in Japan Laser Overlay / Welding Device achieved Higher-Performance and Low Cost.